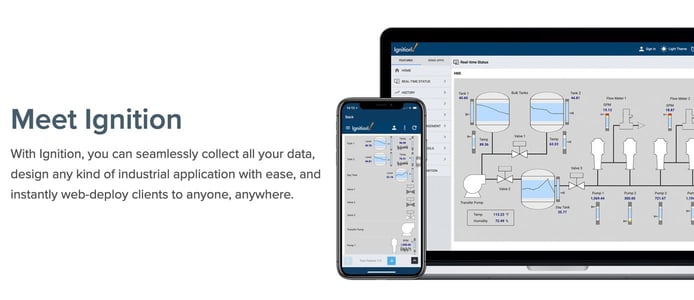

TL; DR: The industrial software company Inductive Automation empowers users to overcome technological and economic obstacles by merging IT solutions with SCADA technologies. The company’s flagship application platform, Ignition, is available under a straightforward server license, allowing for unlimited, seamless data connection and instant deployments on industrial and mobile clients. Now, with Ignition 8.1, Inductive Automation is introducing all-new features for securing and expanding large enterprise systems.

Toronto Pearson International Airport (YYZ), the largest and most frequented airport in Canada, handled 50.5 million passengers in 2019 and is projected to serve more than 80 million annual passengers by 2030.

So when Greater Toronto Airports Authority (GTAA) set out to modernize the airport’s handling systems via its Baggage 2025 program, its first move was to upgrade the airport’s outdated legacy technologies.

The challenge — to replace seven disjointed supervisory control and data acquisition (SCADA) systems with one streamlined solution — was accepted by system integrator Brock Solutions and Inductive Automation.

Inductive Automation’s Ignition platform connects the previously distant IT and OT worlds.

In tandem with its own bagging sorting and reporting software, Brock Solutions implemented Ignition, Inductive Automation’s universal SCADA platform for building web-based industrial applications. The team slowly and carefully replaced each of the seven disparate SCADA systems with the new Ignition system to avoid disrupting airport operations.

The installed system went online in March 2020 and has been used successfully ever since — due, in part, to Ignition’s scalability, stability, and performance.

“We visited the airport with Brock Solutions to understand precisely what the authorities wanted and make sure we could accommodate everything properly,” said Don Pearson, Chief Strategy Officer at Inductive Automation. “Ultimately, they brought Ignition in to replace the existing baggage systems and aggregate them all under one pane of glass.”

The implementation of Ignition at Toronto Pearson International Airport is one of many successes Inductive Automation has made possible in its almost 20-year history. Thousands of companies around the world now leverage the product, available under one simple server license.

Eliminating Technical and Economic Development Obstacles

Inductive Automation’s roots go back to 2003 when an experienced but frustrated integrator named Steve Hechtman decided to tackle the software development side of industrial automation.

“There were a lot of pain points that integrators felt with the available software at the time,” Don said. “The software industry and the big players had a very proprietary mindset toward their technology. There wasn’t a complete solution that incorporated everything he needed to serve his customers better — so Steve decided to create one.”

His initial mission was to move data between standard IP-based technologies like SQL databases and programmable logic controllers (PLCs) on the manufacturing floors of industrial plants.

Ignition was designed to rev up industrial application development.

“He knew that a bidirectional data flow between SQL and PLC could bring value to customers, and the very first release, what was called FactorySQL, did that exact thing,” Don said. “Once that connection was made, users could accomplish wonderful things in terms of data acquisition and utilization.”

After enabling data access, Steve’s next step was to develop an innovative solution for visualizing the data. The result was FactoryPMI, a Java-based plant management interface initially released in 2003.

“Our original developers, Carl Gould and Colby Clegg, were hired right out of the University of California, Davis, computer science program,” Don said. “With their IT expertise, the company was able to converge IT and operational technology (OT), which has always been the goal.”

By 2010, Inductive Automation integrated FactorySQL and FactoryPMI into one platform — Ignition. “We’ve never looked back,” Don said.

Ignition: An Open, Vendor-Agnostic Industrial Application Platform

Don said that Ignition was designed with an open approach to ensure compatibility within the industrial software realm.

“Ignition was designed to be easy to integrate and support,” he said. “It’s vendor-agnostic, it’s cross-platform, and it has an open API.”

Don said that Ignition may be the core platform around which industrial automation customers build their digital transformation strategies — but Inductive Automation recognizes that it is not the only player on the field.

“We’re part of a broad and diverse ecosystem,” he said. “Our willingness to open up and play with others brings the customer a best-of-breed option for building out a digital transformation strategy in terms of architecture, scalability, and functionality.”

Through products like Ignition Edge, industrial automation customers can also affordably capture, process, and visualize data at the remote edge of a network. And with Ignition Edge IIoT (Industrial Internet of Things), users can transform nearly any field device into a lightweight, Message Queuing Telemetry Transport (MQTT)-enabled edge gateway.

Don said these products have evolved as a natural extension of Inductive Automation over the years as the industry increasingly embraces cloud and edge computing.

“There’s a huge demand for the acquisition, consumption, and utilization of data,” he said. “But if you want to have big data analytics, artificial intelligence, machine learning — everything that the cloud has been empowering — you have to get at the operational data. Getting access to that data and building out an enterprise that connects from sensor to cloud continues to be a massive trend.”

Customer-Centric Decision-Making Processes

When it comes to internal development, Don said Inductive Automation’s processes are driven by integrator feedback via its partnership program.

“We do integrator round tables almost every week with our Certified, Gold, and Premier integrators where we share our direction and ask for input,” he said. “We also have a portal that anyone can use to suggest an idea to our development team.”

Inductive Automation serves thousands of organizations around the world and across industries, including water and wastewater, oil and gas, food and beverage, and manufacturing. The portal gives everyone a chance to vote on the best ideas for future development.

“Customers themselves get a chance to evaluate all the ideas, and we look for the ones that are the most important to the most customers,” Don said. “That informs our development decision-making. Because we update our software frequently, customers actually see these voted-up improvements baked into Ignition.”

Ignition’s purchase model, available by the server, is also built around customer need. One server license provides the customer with an unlimited number of runtime clients, tags, connections, and developer seats, allowing teams to build systems to their specifications.

“It’s about freedom: We unleash the innovation of customers so they can build the system they want,” Don said. “And it ends up being thousands of devices and millions of data points. We have oil and gas customers tracking 10-million plus data points across five states and 4,000 oil wells. You can’t do that with traditional systems.”

Other benefits in terms of ROI include operational agility, faster time to market, high performance rates, and accuracy. Chobani, which has the world’s largest yogurt plant, uses Ignition to accomplish multiple tasks in the areas of project and asset management, quality control, and enterprise resource planning.

“Hugh Roddy, Vice President of Global Engineering and Project Management for Chobani, calls Ignition his OT operating system because he uses it for everything from asset management to plant floor operations,” Don said.

Unleashing Complete Power for Full Enterprise Deployments

Inductive Automation released the most recent version of its automation platform, Ignition 8.1, in a beta edition this past September.

Don told us the updated integrated development environment includes all-new features for securing and expanding large enterprise systems.

“In November, it went to full industrial release for production,” he said. “We have 500-plus integrators who are essential in getting our deployments to market. We’re a software company; they’re doing the hard implementation work. With 8.1, and the full development of our Perspective Module for mobile, browsers, and workstations, they now have the complete capability for enterprise deployments.”

HostingAdvice.com is a free online resource that offers valuable content and comparison services to users. To keep this resource 100% free, we receive compensation from many of the offers listed on the site. Along with key review factors, this compensation may impact how and where products appear across the site (including, for example, the order in which they appear). HostingAdvice.com does not include the entire universe of available offers. Editorial opinions expressed on the site are strictly our own and are not provided, endorsed, or approved by advertisers.

Our site is committed to publishing independent, accurate content guided by strict editorial guidelines. Before articles and reviews are published on our site, they undergo a thorough review process performed by a team of independent editors and subject-matter experts to ensure the content’s accuracy, timeliness, and impartiality. Our editorial team is separate and independent of our site’s advertisers, and the opinions they express on our site are their own. To read more about our team members and their editorial backgrounds, please visit our site’s About page.